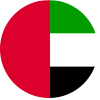

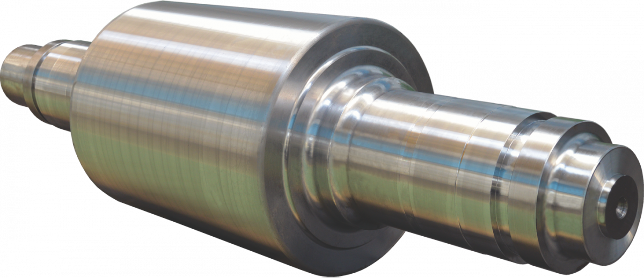

Application: Bar and Rod Mills, Medium and Heavy Section Mills, Seamless Tube Mills

Description: Nodular cast irons belong to a group of cast irons in which most of the carbon crystallises as spherical particles known as graphite nodules. A wide range of properties may be obtained by adjusting the three major alloying elements: Cr, Ni, and Mo. The low nickel grade (ferritic cast iron) provides optimal hardness with high strength and toughness. The medium nickel grade (pearlitic cast iron) has higher surface hardness necessary for intermediate and finishing stands. The high nickel and molybdenum grade (bainitic/acicular cast iron) provide excellent mechanical properties at a high working temperature in terms of strength, toughness and hardness.

Manufacturing process: static or centrifugal casting

Barrel hardness: 40-75 HS

Chemical composition, %:

| Matrerial |

Barrel Hardness, HS |

C |

Si |

Mn |

Ni |

Cr |

Mo |

Mg |

| Ferritic Cast Iron |

40-55 |

2.9 – 3.6 |

1.0-2.2 |

0.4-1.0 |

1.0 – 2.0 |

Max 0.60 |

0.2 – 0.5 |

max 0.04 |

| Pearlitic / Bainitic Cast Iron |

50-70 |

2.9 – 3.6 |

1.4-2.2 |

0.2-0.8 |

1.5 – 2.5 |

0.2 – 1.2 |

0.3 – 0.8 |

max 0.04 |

| Bainitic / Acicular Cast Iron |

65-75 |

2.9 – 3.6 |

1.0-2.2 |

0.2-0.8 |

2.5 – 4.5 |

0.4 – 1.6 |

0.4 – 1.0 |

max 0.04 |